Yoryu Crepe

Yoryu Crepe

This is a process to emboss the fabric in a distinctive way.

Embossing makes the total area of fabric that touches the skin smaller, and therefore, it feels smoother when you wear it.

Pique Yoryu

This is a process to emboss the fabric vertically and uniformly so that it looks like stripes.

There are four types of Pique Yoryu fabrics. The number of stripes per inch determines the type.

The number of stripes per inch are: 10, 13.5, 17 and 19. The most popular type is 17 stripes per inch.

Pique Yoryu is mostly used for underwear.

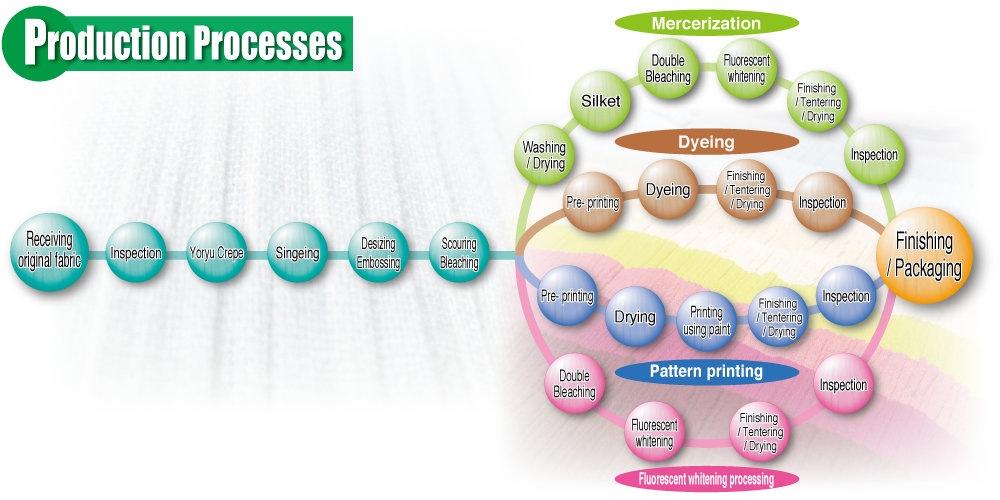

Scouring & Bleaching

Scouring & Bleaching

This is a process to remove resin and cotton residue from the fabric. Additionally, it removes starch that was used during weaving.

This process is necessary to make the next processes (including dyeing, printing and finishing) smoother.

It is possible to bleach 5,000 to 20,000 meters of fabric at one time.

Mercerization

Mercerization

This processing makes the surface of the fabric smooth by making cross sections inflated using alkali chemicals.

The fabric looks shiny like silk when the surface is smooth and it feels smooth and pleasant on the skin.

Printing Process

Printing Process

This process is for printing on fabric.

There are two printing methods. One is Pigment printing, which is printing with paint (printing patterns on the surface of the fabric) and the other is

Dye printing (dyeing the yarn before the fabric is woven).

It is possible to use 5 colors simultaneously during Pigment printing, and the fastest processing speed available is 100 meters per minute.

Dyeing Process

Dyeing Process

This process is for dyeing the fabric in single color using a jet-dyeing machine.

The machine can handle tie-dye and product-dye other than single color dye.

Drying

Drying

This process is for setting and drying the fabric to the proper width.

This involves not only drying but also treating the fabric with chemicals for deodorizing and/or antibacterial purposes.

Finishing

Finishing

This is an inspection process for the finished fabric (product).

Processes for folding and rolling up are both available.

The process is dependent upon the client’s stretching machine.

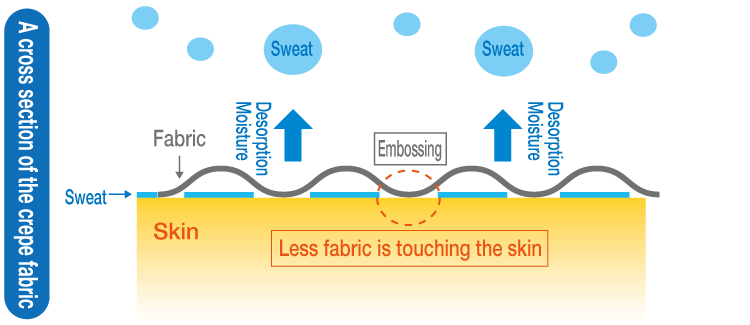

The secret of Takashima Crepe; why it feels cool on the skin!!

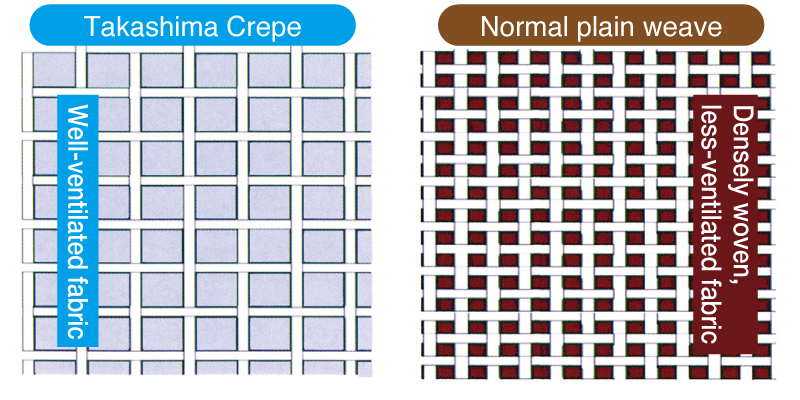

Takashima Crepe is made with hard-twisted weft threads. The weft threads are twisted more than twice as hard as normal threads. This extra twist makes embossing more effective and, as a result, less fabric touches the skin. The thread count is 120 whereas it is 180 for normal weaving so that the gap between threads is larger and it is cooler when you wear it.

These are the reasons why Takashima Crepe can absorb more sweat and dry quicker.

Weft threads are hard-twist yarn so the woven fabric becomes stretchy. Consequently when you wear this fabric, it doesn’t stick to your skin if you sweat and it leaves you feeling cool and fresh.

The characteristic of Takashima Crepe is its variety of embossing including random, straight and wavy. This is possible because Takashima is the production region not just for textiles but also twist yarn.